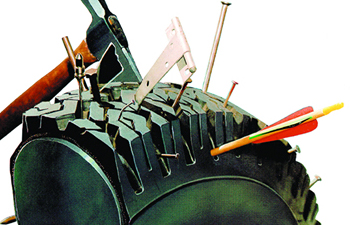

Carlisle’s TLC Tire and Rim Protection™ for OTR Vehicles Features New Neon Red “Leak Alert” Coloring for Enhanced Safety on the Job

ST. LOUIS, MO—February 19, 2019—Carlisle TyrFil (www.CarlisleTyrFil.com) has unveiled a new, vibrant color for its industry-leading TLC Tire and Rim Protection™ that will deliver greater safety and functionality to field operators and drivers of Off-the-Road (OTR) vehicles working in mining and other related industries. TLC is a protective coating that conditions the tire wheel and maintains cooler tire operating temperatures, which helps to eliminate premature failures caused by rust and other deterioration. Carlisle’s most recent TLC Tire and Rim Protection™ formula—to be showcased at this week’s 64th Annual Off-the-Road (OTR) Conference in Tampa, Florida, held February 20th-23rd— features a bright, highly visible “Neon Red” that will enable earlier, safer detection of dangerous tire and rim leaks.

Carlisle TyrFil is best known as the manufacturer of TyrFil™ Flatproofing, the industry’s leading polyurethane tire fill technology for pneumatic tires for heavy commercial and industrial equipment. The company’s TLC Tire and Rim Protection™ technology is another centerpiece of the brand’s complete 360-degree tire care solution. TLC features industry leading corrosion protection that helps reduce equipment downtime by making it easier and safer to dismount tires, which directly helps operators to better manage labor costs. Now, the brand’s new Neon Red coloring will make it far easier for operators to quickly identify and catch the early-stage rim cracks and leaks that can lead to catastrophic tire equipment failure on the jobsite.

Independent color and corrosion testing conducted in fall 2018 by Applied Technical Services, Inc. (ATS), one of the industry’s top tier consulting engineering firms and independent labs, compared Carlisle’s new Neon Red coloring with other leading competitors’ formulas. Results show that TLC’s Neon Red maintained its color visibility and vibrancy, even when other brand color markings had faded.

“Our TLC Tire and Rim Protection™ formula is a mainstay of our end-to-end technology solution offered for the OTR marketplace, and most specifically, the mining industry, where temperature extremes and volatile working conditions can take a toll on tires—creating both performance and safety risks for field operators,” said Mike Arnold, General Manager and Vice President of Carlisle TyrFil division. “The ability to better protect tires on the job, while also ensuring early detection of the most dangerous leaks, cracks and unwanted deterioration, directly saves our mining customers valuable time, money and manpower.”

Weather-borne effects are one of the biggest detriments to mining equipment’s wheels and tires. A signature of Carlisle’s TLC technology is the fact that it maintains cooler operating conditions even when faced with fluctuating temperature extremes of hot and cold. The TLC Tire and Rim Protection™ formula’s superior liquid coating is added to the tire air chamber and coats the inside of the rims to provide rust protection, while offering continual vapor dispersion to extend the life of tires and rims. Plus, TLC is non-toxic, non-flammable, and non-hazardous.

In addition to testing the color vibrancy of TLC’s new Neon Red markings, ATS also conducted a series of rigorous corrosion tests, comparing TLC to other industry leading products. ATS constructed specialized chambers to simulate a year of field use in a mining OTR tire that operates at up to 176°F (80°C) on a two-shift basis. Corrosion testing was conducted at extreme temperatures of 212°F (100°C) and 100 PSI. At the end of the test, the results were clear-cut. The sample steel coated in TLC Pro had only a 0.005% reduction in weight; the competition sample had corroded over 2.6 times as much, with a 0.013% weight loss, providing proof of performance of much higher levels of corrosion protection from TLC products.

Also, internal lab testing conducted extensive evaluation of TLC’s ability to withstand the “freeze test.” TLC and a competitor product were subjected to below freezing temperatures of -10°F (-23°C) for over six hours. The competitor’s product froze solid within one hour. The TLC formulation did not freeze. Even in the most severe operating conditions, Carlisle delivers a TLC product specifically formulated to perform from lows of -40° F to +20° F (-40° C to -7° C).

For OTR operators who rely on the safety of properly maintained tires for their heavy equipment (and especially those working at often dangerous mine site locations), Carlisle’s new color offering and standard TLC performance features play a critical role in better protecting operators and eliminating unwanted productivity downtime due to costly equipment failures.

For more information, please visit www.CarlisleTyrFil.com.

About Carlisle TyrFil

Carlisle TyrFil is a division of Carlisle Construction Materials. Carlisle Tire Fill System’s TyrFil™ Flatproofing, also known as “foam fill,” can be pumped into off-the-road (OTR) pneumatic tires to replace air with a resilient elastomer core that completely eliminates dangerous flat tires in commercial and industrial heavy equipment vehicles. TyrFil™ transfers significantly less g-force resulting in a smoother, safer ride compared to solid aperture tires. Excessive g-force transmission, commonly known in the industry as Solid Shock, can produce premature damage to the equipment and injury to the operator. With TyrFil™ Flatproofing, “We Keep the World Rolling.”