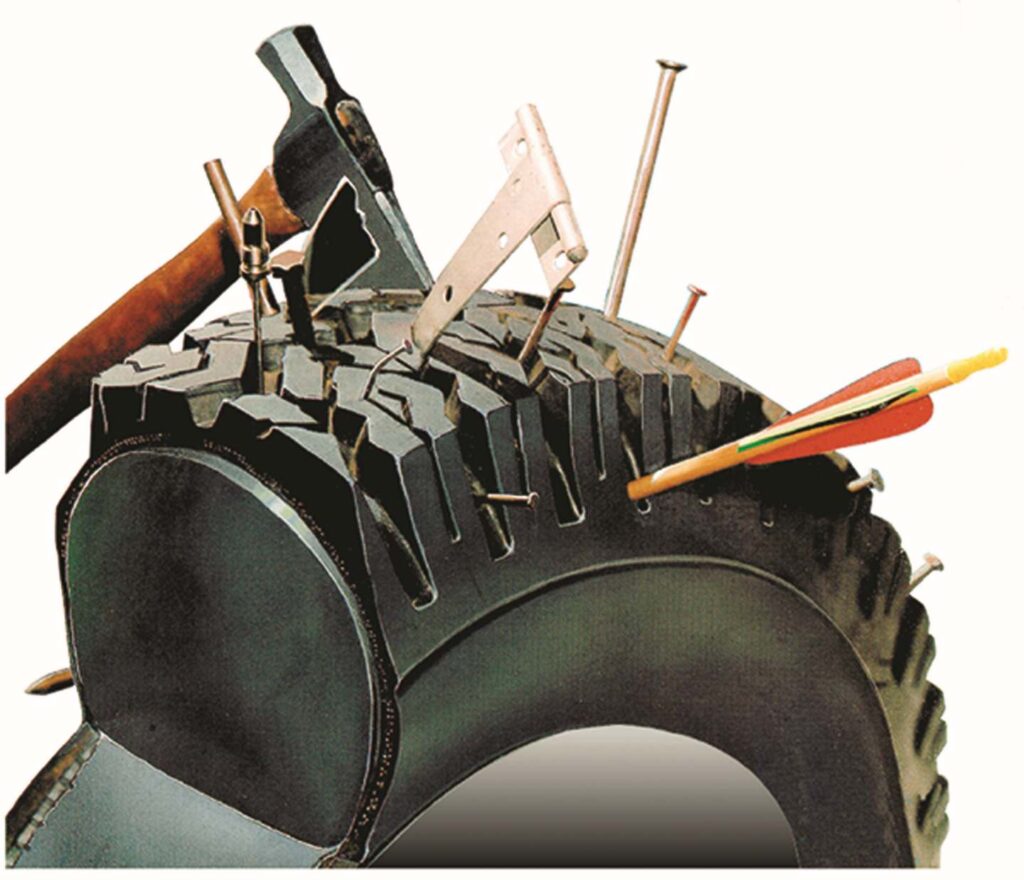

Tire flatproofing is reshaping the way industrial, construction, and material-handling operations think about equipment reliability. Traditional pneumatic tires have served the industry for decades, but they remain susceptible to punctures, sidewall damage, and slow leaks — all of which produce costly downtime. Flatproofing replaces the air inside a tire with a polyurethane elastomer, creating a tire that cannot go flat under normal operating conditions. The result is a hybrid solution offering the cushioning of air with the dependability of solid tires.

At the core of this process is polyurethane foam, a chemistry marvel that expands to fill the entire internal cavity of the tire. Once cured, it acts like a semi-solid core, giving the tire consistent pressure, stable sidewalls, and the ability to carry heavy loads without the risk of pressure drops. Because the foam behaves elastically, it absorbs shock and distributes weight more evenly than traditional pneumatics, especially across sharp or uneven terrain.

From an operational standpoint, the return on investment is clear. A single unexpected flat can halt progress on a job site, delay deliveries, or require emergency repairs. Flatproofing eliminates that unpredictability, enabling teams to schedule maintenance proactively instead of reacting to tire failures. For fleet managers, it means better uptime, fewer service interruptions, and a more predictable maintenance budget.

Flatproofing also contributes to operator safety. Tires with inconsistent pressure can impact steering, braking, and load balance — all subtle risk factors. By creating a stable, non-variable tire core, operations reduce the chance of tipping hazards, load shifts, or equipment instability. As industries push harder for workplace safety improvements, flatproofing has become one of the simplest and most cost-effective upgrades available.