A Simple Guide to Foam Filled Tires

There are multiple options of tires that can be used on Off-the-Road heavy equipment: pneumatics, solid apertures, and filled-pneumatics with TyrFil flatproofing, commonly referred to as foam fill. Tire purchase and maintenance is one of the more significant expenses that heavy equipment owners and fleet managers must consider. Knowing the advantages and disadvantages of each can take some serious time and research – but we’re looking to make it all a little bit easier.

This blog outlines what foam-filled tires are, their benefits, and why people opt to purchase them over air-filled and solid apertures. For specific application advice, contact our team at Carlisle TyrFil today.

What are Foam Filled Tires?

While foam-filled tires may be a technology the average person is less familiar with than other types, this is actually a technology that has existed for more than 50 years. TyrFil flatproofing is a polyurethane liquid that is pumped into OTR tires, replacing all of the air, and cures into a solid elastomer within 24-48 hours. Even in the most hazardous environments, tires filled with TyrFil will never go flat.

Foam-filled tires offer several key benefits including maintaining optimal tire pressure, providing consistent tire deflection and footprint, and increasing traction and stability. Unlike solid or aperture tires, TyrFil offers a choice when it comes to pressure, durometer and tire tread. In other words, you are able to use the exact tire originally specified by the manufacturer. Also, this allows the operator to customize performance per application or environment.

Foam Filled vs Air Filled vs Solid Apertures

While all three leading tire choices offer positives and negatives, it’s worth taking the time to explore the specific operational and financial advantages to each.

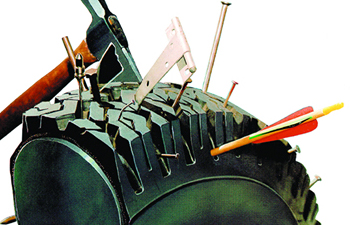

Pneumatic tires offer various cost advantages, but are vulnerable to going flat from nails, screws, and rebar punctures and are more prone to dangerous blowouts. You are more likely to experience premature tire failure due to flats and blowouts. Also, tire flats are not only dangerous to field operators, but they are also costly, as they drain resources, affect the work schedule, decrease on-the-job productivity, and may render serious damage to equipment.

Solid tires are composed of the most stable tire material on the market and can’t be punctured. However, they are limited on sizes, tread patterns, and durometers, and their ride may be rougher for equipment operators. Solid tires also represent a potentially negative impact on the environment, as they cannot be reclaimed as easily as polyurethane-filled tires.

Mounting equipment for solid tires is expensive, and the areas around the holes in aperture tires may be more prone to cracking. That increases tire wear and hastens the end of the tire life cycle. Foam fill eases this risk, helping to extend tire usability and saving operators from incurring costly equipment damage expenses.

Foam-filled tires essentially offer most of the same benefits a set of pneumatic tires do, with the clear distinction of not experiencing leakage through punctures and tears. Over time, all air-filled pneumatic tires are going to lose air – an issue you won’t face if you go foam-filled. Also, the tire fill pressure can be varied to more closely mimic pneumatic tire pressure.

Considering the Ride Experience

The greatest advantage of TyrFil over other No Flat options, including solid aperture tires, is the smoother ride as a result of a substantially lower G-force transmission. Higher G-force transmission can cause operator injury and premature wear and tear on equipment components, and it is the leading cause of Whole-Body Vibration (WBV). The physiological effect may result in worker attrition and job absence due to measurable muscular-skeletal and neurological injury to equipment operators. This is a real occupational hazard, not to be ignored, that can cost construction companies hundreds of thousands of dollars in damages.

Tire fill offers equipment operaters a smoother flatproofed ride that is a closer equivalent to riding on air. Although air-filled pneumatics on average offer a softer ride than both solid apertures and foam-filled tires, it is bouncier. While they can offer a float-like ride, their air pressure must also be constantly monitored and maintained to ensure safety and performance.

We’ve walked you through the benefits of a foam-filled tire. They last longer than air-filled tires, offer a smoother flatproofed ride and more choice than solid apertures, and are a reliable option for most job sites. So, what’s the downside? Foam-filled tires are more expensive initially then a pneumatic tire but have a better ROI over the lifetime of the tire. Check out the profit analysis tool to calculate the savings you will realize by using foam-fill instead of air-filled pneumatics.

Contact Carlisle TyrFil for Professional Advice

Reading through price comparisons or pros and cons lists will only get you so far. When it comes to selecting the right type of tire for the application, you don’t want to leave any room for error. This is why you should always, always work with an expert to ensure you’re making a long-term investment that will pay off every single day you operate your equipment.

At Carlisle TyrFil, we and our dealer network know tires. We work with clients to ensure they make a purchase they aren’t going to regret in a few months’ time. If you’re wondering whether foam-filled tires could be the right option for you, we’re ready to lend a hand. Contact our team today to chat with a tire expert, and let’s find your perfect match today.