The Many Safety Advantages of TyrFil™ Flatproofing Technology

When it comes to enhanced tire and vehicle safety on the job site, nothing performs for heavy Off-the-Road (OTR) equipment like TyrFil™ Flatproofing, a polyurethane tire fill manufactured by Carlisle TyrFil™. TyrFil™ Flatproofing technology, and the array of tire safety-promoting conditioners and sealants now readily available to the marketplace, is a game changer for field managers who want to keep their operators safe—and their productivity high.

If you work in a busy construction, mining, agriculture, waste management or even military environment, you already know that operator protection protocols should always be first and foremost: Most importantly, for the health of your valued workforce, and second, to ensure that your project management is flawless and without incident. When OTR heavy equipment is exposed to the rigors of hazardous conditions, proper tire performance and flatproofing are essential components of a successful overall operation.

Anyone who has worked extensively in the field using heavy commercial and industrial equipment—from Front End Loaders to Skid Steers, Telehandlers, Rough Terrain Forklifts, and more—understands the realities of the occupation: your equipment is more prone to flat tires due to the excess debris and harsh conditions encountered. Ensuring that these vehicles remain free of dangerous tire flats at all times is absolutely paramount. An unanticipated flat can place any OTR or oversized vehicle at risk—in the worse-case scenario, at danger for tipping over and seriously injuring operators, and, in the best case scenario, for taking key operatives and equipment out of commission and potentially bringing your job site to a complete standstill. When this happens, everyone involved suffers—and the irony is that it’s totally preventable by selecting a smart tire solution for an OTR environment.

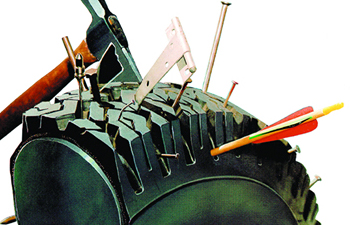

When it comes to coupling vehicle performance and cost considerations with worker safety, nothing beats choosing TyrFil Flatproofing, commonly referred to in the industry as foam fill. TyrFil can be easily pumped into any pneumatic tire to replace air with a synthetic elastomer core that eliminates flats to ensure a smoother flatproofed ride for operators and vastly reduces tire wear, tear and denigration to costly equipment. TyrFil guarantees that tires will remain virtually “flat free” at all times. Because using pneumatics filled with TyrFil allows equipment to operate over broken glass, nails, sharp metals, rocks, rebar, and other damaging objects, this type of tire flatproofing technology enables OTR machinery to literally glide across debris that would quickly puncture traditional air-filled pneumatics.

The durability of polyurethane tire fill has been proven to perform in this capacity time and time again – in literally thousands of demanding applications for the construction, waste management, mining, municipality, military and rental equipment markets. And Carlisle’s market leading TyrFil™ Flatproofing line has proudly led the industry now for the past nearly 50 years.

Why is a flatproofing solution important?

There are many performance advantages to TyrFil™ Flatproofing technology that also have an indirect safety impact – and there are also myriad more obvious and direct safety advantages. Ultimately, anything related to shock resistance, cushioning, stability and traction plays a key role in keeping OTR heavy equipment and their operators safe.

First, pneumatics filled with TyrFil™ offer a reliability and resilience that competitive technologies do not have:

- They eliminate virtually all tire flats from puncture.

- There are less tip-overs due to sudden flats with TyrFil™ Flatproofing technology.

- They provide better ballast for steep hillside jobs or unusual overload conditions.

- They eliminate the potential for tires or wheels to fail with explosive force, oftentimes due to loss of air pressure.

- Operators will experience fewer bent wheels using TyrFil™.

- There is typically less mechanical downtime from tire malfunction.

Second, TyrFil Flatproofing technology supports enhanced worker safety in immeasurable ways:

- Carlisle TyrFil™ in particular offers a “softness” of 8 durometer that is great for skid steer applications, especially because this type of equipment does not have shocks, and this can impact both vehicle and operator safety.

- With less unanticipated flats comes greater operator control.

- TyrFil Flatproofing technology also offers superior heat resistance—tires last longer and are more durable on the job.

- Using pneumatics filled with TyrFil™ Flatproofing may also help protect operators and machines from the harsh ride and jolting vibration of Whole Body Vibration (WBV) – a serious form of occupational impact that may cause serious medical effects including muscular-skeletal, excessive headaches and worker fatigue.

Deters damaging g-force impact

This unwanted g-force vibration can be taxing on drivers who are stationed behind the wheel of an OTR vehicle for many hours at a stretch. Because TyrFil™ Flatproofing can absorb g-force vibration more effectively than solid apertures, pneumatics filled with TyrFil™ Flatproofing deliver a smoother, more consistent ride that’s both safer and more comfortable for equipment operators—helping to prevent potential injuries that can jam productivity.

The reduced jarring—made possible with TyrFil™ Flatproofing—also decreases the wear, tear, and deterioration on expensive operational equipment and eases strain on its components, eliminating added maintenance downtime that would equate to far more overhead than the cost of a new tire. While solid tires are known for being stable, puncture free and reliable in the field, there is nothing about solid or aperture tire technology that can prevent the hard, rugged impact of what’s referred to in the construction and OTR industries as “Solid Shock.”

In fact, Carlisle™ TyrFil™ products have undergone extensive comparative field testing at the leading independent automotive proving grounds in the U.S. – TRC, Inc.—which concluded that using pneumatics filled with TyrFil™ Flatproofing transmit less g-force and vibration to operators, which equates to a smoother and safer ride.

* * * * *

For anyone reliant on the high productivity of an OTR heavy equipment fleet, TyrFil™ Flatproofing is a safer, more resilient choice that can save time and money in a way that positively impacts both operator health and well-being, and supports the project bottom-line. Our TyrFil™ Flatproofing technology is the central brand line within Carlisle’s complete 360-degree tire care solution that also includes our TLC Tire and Rim Protection™ (which protects wheels from unwanted corrosion and rust and weathering from extreme elements, including sub-zero freezing conditions, to extend tire and wheel life) and our ReSeal™ industrial grade sealant offering Dupont™ Kevlar® (a durable, high tenacity fiber that is 5X stronger than steel) to deliver additional “tough job” puncture resistance.

For more information, please continue to follow our Carlisle™ Tire Fill Blog and learn more about “safer choice” tire technology options.

Dupont™ and Kevlar® are trademarks or registered trademarks of E.I Dupont de Nemours and Company.

Read related news: A Deep Dive Into the TyrFil Advantage Over Solid Aperture Tires