Carlisle TyrFil: “Battle Ready” Where It Matters Most

Construction and commercial operators often talk about their industrial equipment performing well “in the trenches” when put under duress, but virtually no workplace scenario tests equipment and tire technology performance like the actual military combat environment.

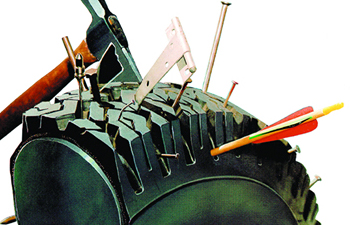

Carlisle TyrFil, formerly known as Accella Tire Fill Systems, has delivered a proven flatproofing solution for the Off-The-Road (OTR) tire and industrial equipment industry for the past four decades. The industry’s leading “no flat” technology has enabled costly commercial equipment to virtually glide over dangerous work site debris, such as glass, nails, rebar and sharp rocks without incident—saving job operators invaluable operating overhead and, most importantly, keeping work crews safe out in the field.

But TyrFil technology has also proven itself equally competent in an even more rigorous performance field—the military combat theater. No where is TyrFil’s injectable polyurethane tire “foam fill” more effective, or essential, than in the military arena—where lives, resources and logistical strategy literally depend on the safety of military grade tires and the vehicles they support.

TyrFil’s RePneuTV Ballistic No-Flat Technology delivers a truly state-of-the-art flat free guarantee for field managers looking to increase safety in actual, live military engagement—and ensure that their vehicles and equipment remain operational even in highly dangerous combat scenarios. RePneuTV is an extreme-resilience polyurethane formulation injected into military grade pneumatic tires. This high-performance ballistic proof technology truly pushes the envelope of speed and load to new levels in a host of challenging driving conditions that might typically confront military troops in action.

This formulation is not designed for everyday vehicles. It’s a heavy-duty composition specifically able to meet performance criteria for military and security forces, whose vehicles face far more rigors than typical commercial applications. RePneuTV flatproofing solution enables troops to move into high-risk combat areas, armed with extra tire protection so they can pursue their missions, run drills, and return to or reach designated safety zones even if tires are interdicted.

Hallmarks of the RePneuTV formulation include:

- Bulletproof performance

- Total elimination of tire flats

- Catastrophic blowout prevention

- Shrapnel and other field debris resistance

- Less damage from IED blasts

- Increased and better traction and tire wear

- Enhanced vehicle stability

- Less g-force vibration (which equals a smoother, less bumpy ride for operators)

This tire proofing technology is also ideal because it can literally resist the impact of bullets and shrapnel. Tires filled with RePneuTV can withstand small arms fire or even .50 caliber fire—and still perform efficiently, even after taking direct hits. This capability of the technology to truly perform “under fire” means that it can help military personnel to save more lives in the heat of combat in real time.

Adding to its reliability when the stakes are the highest, RePneuTV has also undergone extensive performance testing—both in the laboratory and in a field environment. The testing included off-road and over-road with general endurance, high-speed rally, pursuit and evasion, road spikes, slalom, braking, pitch and roll, cornering, climb and descend, traction, and ballistics.

Two classes of vehicles (operated by highly trained former US Military and Department of Defense personnel) were utilized during the professional driver testing: 1) a Lexus (simulated armored vehicle), and 2) a Toyota Tacoma pick-up (soft vehicle) filled with RePneuTV at manufacturer’s suggested PSI (80 PSI) loaded and unloaded. Speeds started at 30 mph as a warm-up moving to 50, 60 and 70 mph. At each interval, the independent test analysts examined assemblies for any damage and temperature impact—even using infrared (IR) pyrometers. The test crew also recorded data for the wheel, sidewall and tread areas of the assembly. Temperature graphs were additionally plotted and taken externally to ensure that there was zero impact from thermal degradation.

In each of these trials, RePneuTV exceeded expectations, ensuring that military vehicles utilizing RePneuTV Ballistic No-Flat Technology are equipped to confront almost any tire challenge they might come across in live battle. Even while hitting and sustaining a 100-mph mark on the endurance phase, the tires performed flawlessly—making them an optimal tire technology selection to assist troops on field missions that require military personnel to remain expeditionary and mobile, and helping them return, without tire incident, to safety zones…even in extreme scenarios.

For more information, please visit www.carlisletyrfil.com.